When the bobbin and top thread get tangled together and create a giant knot of thread, you’ve just experienced what machine embroiderers like to call…

Bird nesting.

You can spot bird nesting if you’re seeing messy loops on the top or bottom of your embroidery.

It usually looks a little something like this…

Bird nesting can cause your garment to be pulled down into the opening where the bobbin is released from the needle plate. This can cost you money, because it may create a hole in your garment if unattended.

Therefore, it’s crucial to pay attention to possible indications of bird nesting as the machine is running.

When or if bird nesting does occur…

Inspect the area underneath the garment near the needle plate, and cut the clump of thread loose from the garment.

However, the best case scenario is to try avoid it altogether.

That’s why, in this article, we’ll be discussing the five main reasons why bird nesting occurs:

- Improper top threading

- Incorrect thread tension

- Improper bobbin threading/placement

- Improper hooping

- Lack of maintenance

Read on to see why each of these mistakes causes bird nesting and how you can prevent bird nesting from happening in the future. You can also check out our Embroidery Hub episode above where we talk all about bird nesting!

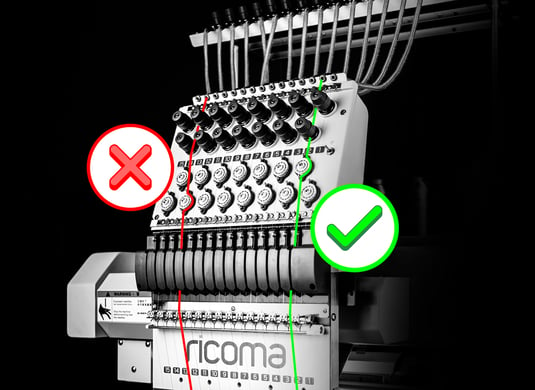

#1: Improper top threading

Proper threading is the key to guaranteeing your machine runs smoothly.

If you miss a point in the thread path that adds tension to the top thread, the top thread can actually get caught in the hook when you begin the embroidery process.

This can cause your hook to freeze up and slow down your entire embroidery process. If you’re new to embroidery or need a refresher on threading, click here to learn how to properly thread your embroidery machine.

#2: Incorrect thread tension

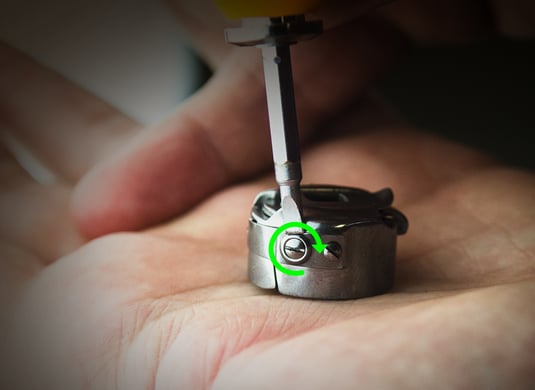

Improper thread tension is one of the main reasons we experience bird nesting.

If your bobbin tension is too loose, extra thread may unwind from the bobbin, which ultimately causes a buildup of thread underneath the needle plate.

In this case, tighten the bobbin tension by turning the tension screw on the bobbin case clockwise.

Overall, in order to prevent bird nesting and many other machine embroidery issues…

You’ll need to start with proper tension.

#3: Improper bobbin threading/placement

In some cases, the bobbin can be at fault if it has not been wound or threaded properly, which can cause it to snag and not run smoothly.

Bird nesting may also occur for simply forgetting to insert the bobbin case into your machine or if you insert the bobbin incorrectly.

As silly as it sounds…

It’s happened to almost every embroiderer at some point.

#4: Improper hooping

In machine embroidery, flagging refers to when the fabric bounces up and down during embroidery. This usually happens if the fabric is hooped too loosely, causing it to slip or expand in the hoop.

Improper hooping makes it harder for the top and bobbin thread to “catch” and run together smoothly, ultimately causing bird nesting.

Improper hooping also causes flagging, which is the real reason why we get bird nesting.

Flagging occurs mostly on caps, seeing that the cap ring itself sometimes prevents the cap from lying entirely flat.

If you’ve been running into cap embroidery issues such as bird nesting on caps, click here to download a FREE cap embroidery guide that will help you prepare your caps for a smooth production run and reduce flagging.

#5: Lack of maintenance

.jpg?width=535&name=lack%20of%20maintenance%20(1).jpg)

If you’ve covered all your bases, and are still experiencing bird nesting…

It may be time to clean your machine.

Has your top thread been shredding and possibly leaving pieces in the upper thread path? Are there pieces of lint or thread hiding under or around the bobbin case?

An unkept rotary hook area can cause thread breaks and bird nesting. Therefore, make sure to clean the area underneath the needle plate with a small brush or a can of compressed air. Click here to watch a video on proper embroidery machine maintenance.

Bottom Line

Bird nesting is more than a simple nuisance. It can reduce productivity and even ruin items beyond repair. More importantly, it’s an indication that you may be making simple mistakes that are costing you time and money.

If you’re frustrated with bird nesting or other embroidery issues, it may be due to simple embroidery user errors. If that’s the case…

You’re not alone!

Take advantage of the support in this industry and join our Facebook group, Embroidery and Printing Business Help.

In it, you can ask questions, post photos and meet other passionate embroidery enthusiasts who discuss ways to overcome these challenges.

Are you curious how Ricoma can help your custom apparel business?

Schedule a call for a Quick 30 minutes “Embroidery Talk” with our specialists to see if you’re really ready to start or expand your business. Our specialists can help you…

- Find helpful resources to kick start your embroidery education

- Answer any questions regarding pricing your items for profit and sourcing materials

- Help you compare and contrast different machine types and branch in the industry

- Help you determine which machine would suit your business based on your current and future goals